Want to give your car a boost in performance and efficiency? Installing a turbocharger is an effective way to increase your vehicle’s horsepower without breaking the bank or spending days in the garage. Turbochargers compress more air into the engine’s cylinders, allowing for more fuel to be added and thus increasing power output.

Turbocharger installation might sound complex, but with the right tools and guidance, it can be a straightforward DIY project. This blog post will walk you through each step of the installation process, ensuring you can enhance your engine’s performance without needing professional help.

From selecting the right turbocharger to fitting it properly, you’ll find all the essential information to get your car running more efficiently. Whether you’re a seasoned mechanic or a DIY enthusiast, this guide will help you unlock the full potential of your vehicle with a turbocharger.

Understanding Turbochargers

Turbochargers significantly enhance engine efficiency and power by increasing air intake pressure. This can lead to better performance and fuel economy.

Basics of Turbocharger Function

Turbochargers work by using exhaust gases to spin a turbine, which then powers a compressor. The compressor draws in ambient air, compresses it, and forces it into the engine cylinders at higher pressure. This increases the amount of oxygen available for combustion, leading to more powerful explosions within the engine. As a result, the engine generates more power without a corresponding increase in fuel consumption.

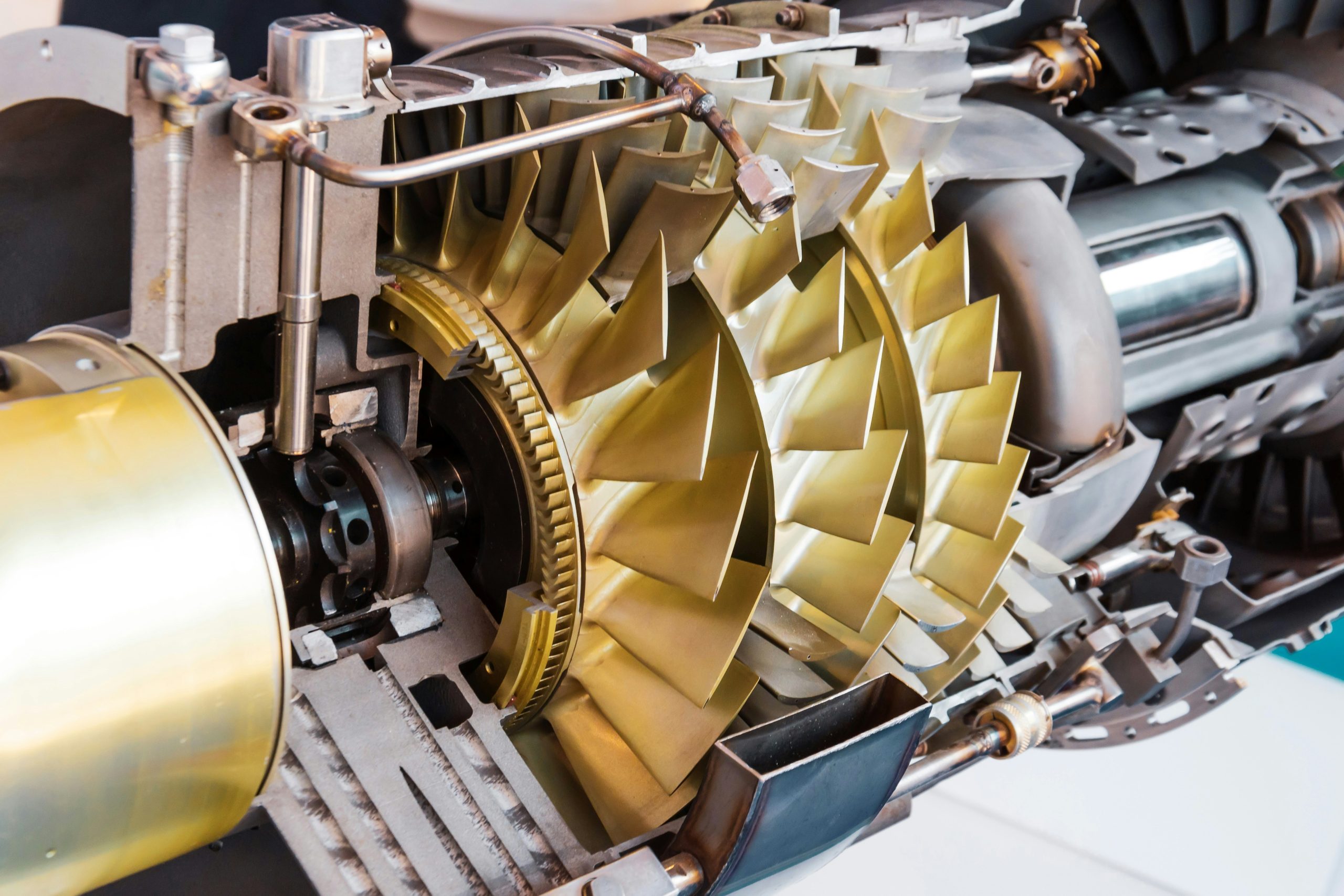

Components of a Turbocharger

A turbocharger consists of two main parts: the turbine and the compressor. The turbine section is connected to the exhaust, where it captures and utilizes the energy from hot gases exiting the engine. This energy drives the compressor section, which is connected to the intake. When the compressor operates, it compresses the incoming air and sends it into the engine at increased pressure.

The Role of the Compressor and Turbine

The compressor and turbine sections of a turbo work together to increase engine efficiency. The compressor, driven by the turbine, increases the air pressure entering the engine, while the turbine harnesses energy from exhaust gases. This balance is crucial, as the compressor must deliver the right amount of air to improve combustion without overwhelming the engine. Proper operation of both components results in optimal boost pressure and improved overall performance.

Pre-Installation Planning

Proper planning is crucial to ensure a smooth DIY turbocharger installation. Key aspects include evaluating engine specifications, selecting the right turbocharger, and assembling necessary tools and materials.

Determining Engine Specifications

Before any turbocharger installation, knowing the specifics of the engine is fundamental. It’s important to determine the engine size, type, and current condition. Whether it’s a 4-cylinder, V6, or V8 will influence compatibility and performance outcomes.

Failure to match the turbocharger to these specifics can lead to suboptimal performance or potential engine damage. Review the engine’s service history for any repairs or modifications. It’s also helpful to check the manufacturer’s guidelines for maximum boost levels and acceptable working pressures.