Choosing the Right Turbocharger

Selecting the correct turbocharger involves considering both engine size and desired performance gains. Small engines, such as 4-cylinder models, typically benefit from smaller turbochargers which provide quick spool times and improved throttle response.

In contrast, larger engines like V8s can support bigger turbochargers that offer higher power output but may take longer to spool. It’s also crucial to choose turbochargers with compatible flange types and connection ports. Researching brand reputation and user reviews can aid in making a sound choice.

Tools and Materials Needed

Gathering the proper tools and materials is essential for a hassle-free installation. Basic tools like wrenches, screwdrivers, and pliers are necessary. Specific tools such as torque wrenches, intercooler piping, and oil feed lines will be required.

You may also need custom brackets or mounting points depending on your engine setup. Ensure all gaskets, seals, and hardware provided with the turbocharger are intact. Preparing these items before beginning the installation can prevent interruptions and ensure a smoother process.

Installation Essentials

This section provides key tips for safely and correctly installing a turbocharger, emphasizing safety measures and understanding proper placement.

Safety Precautions

Before starting the installation, it is vital to prioritize safety. Ensure the vehicle is on a stable surface to prevent accidents. Wearing protective gear like gloves and safety glasses can prevent injuries from sharp or hot parts. Disconnect the battery to avoid electrical shorts.

Well-ventilated areas are crucial. Working in a poorly ventilated space can lead to inhaling harmful fumes. Having a fire extinguisher nearby is advisable. Using the correct tools is essential. Improper tools can lead to broken parts or injury. Taking time to double-check each step can avoid costly mistakes and ensure a safer process.

Understanding Turbo Placement

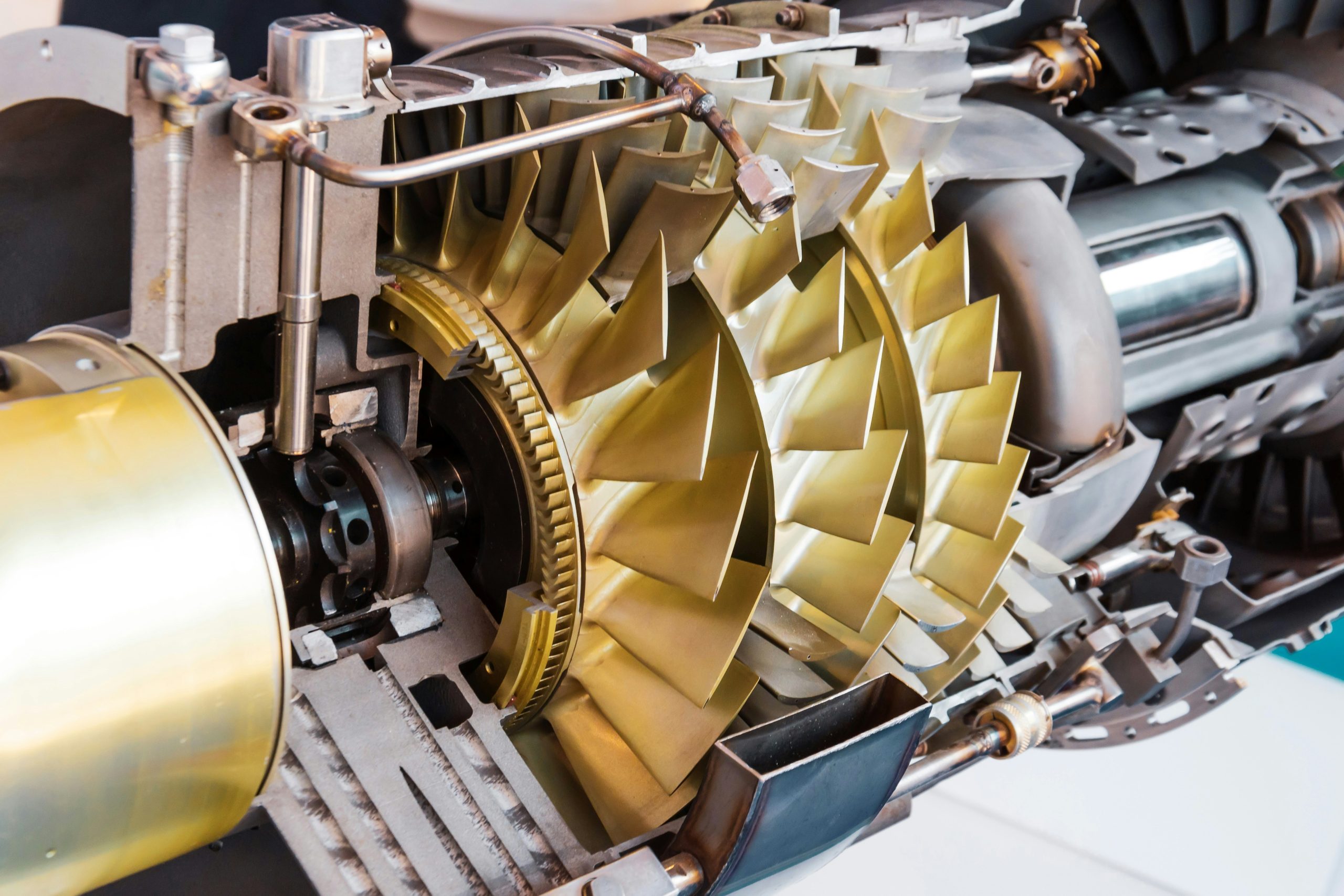

Correct turbo placement is crucial for optimal performance. The turbocharger should be located close to the exhaust manifold. This minimizes the distance exhaust gases need to travel, enhancing efficiency. Ensure that there is enough space for the turbocharger and associated piping. Crowded installations can lead to overheating and performance issues.

Pay attention to the oil and coolant lines. These need to be correctly routed to avoid leaks and overheating. Proper alignment with the existing exhaust and intake systems is necessary. Misalignment can lead to backpressure and reduced performance. By ensuring proper placement, you can maximize the turbocharger’s efficiency and lifespan.

Prepping the Vehicle

Before installing a turbocharger, it’s crucial to prepare the vehicle by gaining access to the engine and exhaust manifold and removing specific components to create necessary space.

Engine and Exhaust Manifold Access

Accessing the engine and exhaust manifold is an essential first step. The hood must be propped open and secured. It’s often beneficial to disconnect the battery to avoid electrical mishaps during the process.

Ensure the engine is cool before beginning. Removing the engine covers and any protective shielding will provide better visibility and access.

The exhaust manifold must be exposed, which might involve removing heat shields. This setup ensures that all connections can be reached without obstruction. Proper illumination and tool organization will streamline the process.